This blog post is an in-depth exploration of one of my earliest self-built RC Cars: The Tamiya Clod Buster. Prepare to be enthralled by the sheer power and innovation of this remarkable machine. Released on September 21, 1987, the Clod Buster quickly became a sensation in the world of remote-controlled vehicles. I vividly recall the momentous occasion when I acquired mine in mid-1992 from a distinguished store situated in my beloved hometown of Speyer, nestled in the southwest region of Germany.

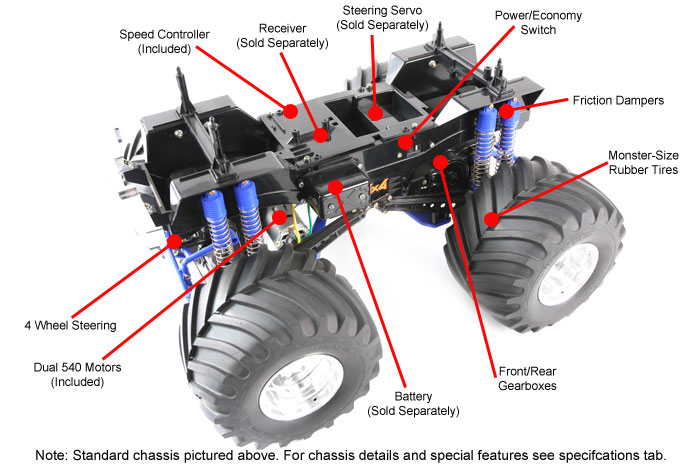

Allow me to elucidate upon the awe-inspiring features that made the Clod Buster an indisputable triumph during its time. With its remarkable 4 wheel drive and 4 wheel steering capabilities, this electric monster truck transcended all expectations. Propelled by two formidable Mabuchi RS-540 motors, its raw power was finely controlled by a mechanical speed controller, featuring a dynamic Power/Economy switch.

Immerse yourself in the rich nostalgia that emanates from this captivating piece of history. Join me on a journey that will pay homage to the iconic Clod Buster and its enduring legacy.

I painted my Clod Buster blue at first, but later I repainted it purple (see pictures). Please, please, don’t ask why purple. I think the reason was that I was tired of the blue and I only had this paint at home. Initially, I took great care of the Clod, painting the indicators, installing the lights, and even wiring all the lights on the roll bar! Unfortunately, later on, the car became more and more used for just bashing.

The Clod Buster was last used around 1997 and ended up in a box in my basement. This was also the time I stopped RC racing for a long time! I started with RC again in 2008 with a 1/5 scale FG touring car! Several moves later, I wanted to get rid of old stuff in some of the boxes. But somehow I couldn’t let go of the mighty Clod Buster, even though it looked terrible. And even though my RC career has evolved – racing 1/5 scale gas-powered cars, 1/10 and 1/8 fully carbon fiber electric racing cars – I was nostalgic and began to create a plan to get the Clod Buster moving again and teleport it into the 21st century!

Drawbacks

But before talking about how the overhaul went, I wanted to spend some words on the drawbacks of the construction of the truck. First, it was constructed very, very simply. It had a mechanical speed controller with only two speeds in each direction. By using a Power/Economy switch, you could adjust to the terrain. This was done with a giant resistor at the back of the car. It basically burned the unneeded electricity. This, of course, isn’t state-of-the-art anymore and even was annoying back in the time.

The steering is one of the biggest problems of the truck. The turning circle is gigantic, even though it had four-wheel steering. This was mostly because of some problems with the standard linkage between axles and servo. Also, the standard size servos in the 90s were far too weak! They had plastic gears and a maximum power of around 4-5kg. Both result in poor steering.

Lastly, the power of the motors. Back in the 90s, only brushed motors were used in models of that size. The 540 motors from the Clod Buster allowed it to be quick – but not really fast. For example, what you could want from a car like that, it couldn’t do a wheelie.

So, besides having the exterior and the styling of the car right and repairing the broken parts, resolving the drawbacks was the main focus of my overhaul.

The Overhaul

Motors / Speed Controller

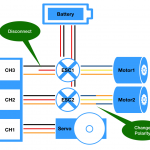

The first thing I wanted to get sorted out was the motors and the speed controllers. Of course, the first thing that came to my mind was using brushless motors. Also, because I tested a 2S lithium polymer battery, I use for my 1/10th scale XRay T4 and my 1/8th scale Buri, fits perfectly into the standard battery bay. I had some experience with brushless motors but only with sensored motors. Because the Clod Buster has two motors, one on the front and one on the rear axle, one motor would need to be changed in polarity. Also, connecting two motors to one ESC is not possible. So, in the end, I decided to use two unsensored brushless motors in combination with two ESCs. High-Class ESCs and motors are expensive, so I did some searching on eBay and found this combo.

For around 30€, it’s good value for money! The motor has the same size as the standard Clod Buster Engine and fits nicely into the chassis. It is even a little shorter and definitely lighter than the stock one. It is made for off-roading, so it has no cutouts for ventilation – which means that no dirt can get into the motor. It cools itself through the ribbed body.

For one axle, the polarity of one motor needs to be changed. Especially if you use a Y-cable to attach both ESCs to the receiver. Each ESC would get the same signal, but one motor needs to spin in the other direction.

Therefore, you just have to switch the outer two cables: orange and blue. If you use a three-channel receiver and you have a transmitter that can mix two channels, you can also use the third channel for the second ESC. Nevertheless, I would recommend changing the polarity so that you don’t have to do that in the transmitter. It makes configuration a little easier. I used the third channel on my Futaba 4PX for the second ESC. Mainly because I wanted to change timings in acceleration and braking between the two axles – to prevent accidental wheelies or rollovers under braking.

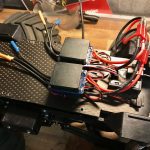

Mounting the components

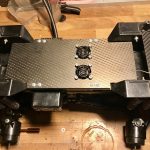

Mounting the motors, of course, is no problem, since they fit nicely to the original mounts. But attaching the two ESCs cleanly into the chassis was a challenge. The old receiver box/chassis cover didn’t have enough space. In addition, all cables would need to go down to the motors, and I would have to extend them somehow. Also, this wouldn’t be a clean look. Because I had some carbon fiber lying around, I decided to cut out a new top-deck with two holes for the fans of the ESCs. This would also give me the possibility to somehow attach them somewhere and guarantee fresh air for the fans even though they are inside the chassis. To prevent little stones from destroying the fans, I mounted two little 30mm fan covers.

This created a nice and clean look and gave enough space to hide ESCs, receivers, and cabling under the cover. The carbon fiber cover is mounted with the original screw holes.

Because one of the bars between the body posts was broken, I also decided to replace both. This would also create a nice and clean look, and I would get rid of the original resistor-mount. To fit the Lithium Polymer 2S battery into the original battery-mount, I just had to open the top of the original cover so I could access the connectors of the battery. The rest of the battery-bay is original.

Steering

The first part of the steering is the steering servo. Back in the 90s, there were only very weak standard-size servos with plastic gears. I had a spare Thunder Tiger DS1015 Digital High servo. It has a 14.5kg positioning force and metal gears. Enough to do the job! But the result was disillusioning. The wheels barely moved when not in motion, the front steering angle was less than the rear steering angle, and the steering was very indirect.

The first thing I did was to eliminate the wobbly steering by deactivating the integrated servo-savers on each axle (see picture for names of the parts). I removed the BC2 screw and pulled out SP1 and BR2. Then I just added a washer on top of the B2 servo horn and tightened the screw BC2 again. Not too much – the steering should still be able to move without resistance.

The second step to get a smaller turning circle is, to use a bigger servo horn on the servo. The standard one is quite small and has a width of about 20mm from the ball connector to the ball connector. I used one that has around 30mm in diameter. When choosing a servo horn, also look after one that is able to handle the force. Many servo horns of standard servos are very weak and tend to bend when using a very strong servo. You can use aluminum servo horns of course but I had a quite strong round, disk-shaped one, laying around so I used that. With the new servo horn, we now have much more movement in the steering and, if the Clod Buster is lifted from the ground, all wheels moved nicely.

Again a disappointing moment came when I put it on the ground and tried the steering while not moving. The front wheels didn’t move as far as the back ones. The reason for that is, that the linkage of the front steering goes upwards and isn’t horizontal as the one on the back (see picture). The result of that was, that the linkage started bending when pushed forward. To resolve this, the links have to be as horizontal as possible.

To get the link to the front horizontal, I had to do some modifications to the front-link on the gear casing. I had to move it from the upper side of the arm to the lower side. To get this to work I had to modify the link a little (see picture). By doing so I got it nearly horizontal and the steering performance improved drastically. The Clod Buster will never be a handy and compact-to-drive-car but with these modifications, it’s much better than the original setup.

Optical overhaul

Of course, also the look of the car had to be improved! First was the paint – the ugly purple had to disappear! I decided on Tamiya TS-6 matt black paint. I had to prepare the old body first, painted the doors white and added a cover in the form of the Punisher logo. Then I painted the body black in two layers and removed the Punisher cover. Because the rims already yellowed a lot, I had the choice of replacing them with chrome rims of the Super Clod Buster or to paint them. I painted them black, with the same paint as the body, as an experiment, and it looked very nice!

Secondly, I removed all the red plastic parts (the F-Parts) and replaced them with new black ones from the Super Clod Buster. Also, some chrome parts, like the bumpers, roll bar and grill needed replacement. Last but not least I couldn’t resist and I put two red LEDs into the headlamps.

Last but not least I had to build a wheelie bar because I had achieved my goal of being able to do a wheelie with the Clod. So I built a wheelie bar from two carbon fiber triangles and mounted it to the back of the chassis. I’ve seen solutions of wheelie bars mounted to the differential case (so very close to the ground) but I wanted to have a realistic look and a high angle of the wheelie! 😉

Pictures

I hope you liked the description of my modifications to my 26-year-old Clod Buster. If you have comments or feedback, feel free to add them to the comments.

Did you use ball bearings in the clod?

If not, why?

No, I haven’t used ball bearings yet – actually a good idea!

The reason is, that, till now, I haven’t thought about it and, till now, it wasn’t one of the major issues of my Clod. Other issues, like motors and steering, appeared much more urgent. Also, I do not drive it a lot – so the added benefit of ball bearings might not be so high in terms of less friction and wear.

But now you mentioned it … there might be a third Clod Buster article with further improvements 😉